Sponsored by Trace Analytics

By Molly Natchipolsky, FireRescue1 BrandFocus Staff

Every day, firefighters face numerous risks and hazards and rely on their personal protective equipment (PPE) to help them stay safe. Unfortunately, some hazards are less apparent than others, such as limited oxygen and exposure to respiratory toxins. A self-contained breathing apparatus (SCBA) filled with unregulated or irregularly tested compressed breathing air can contain contaminants that pose significant risks to firefighters, including:

- carbon monoxide

- carbon dioxide

- oil mist

- particulates

- hydrocarbons

- water vapor

To help reduce these risks, The National Fire Protection Association’s 1989: Standard on Breathing Air Quality for Emergency Services Respiratory Protection was created in 2002.

“NFPA 1989 is all about personal health and safety for firefighters,” said Ruby Ochoa, president and owner of Trace Analytics and a member of the NFPA 1989 Technical Committee. “The bottom line is that anyone who breathes compressed air needs to understand NFPA 1989.”

NFPA 1989 evolved from three separate standard documents – NFPA 1404, NFPA 1500 and NFPA 1981 – which addressed different requirements for breathing air quality. Since 2003, NFPA 1989 has required quarterly testing of compressed air breathing systems by an accredited laboratory. If the system fails testing, the compressor must remain out of service until the air quality passes laboratory testing.

Testing should also be conducted if contamination is suspected or if any alterations, maintenance, repairs or relocation of the system occur. Additionally, NFPA 1989 requires that air samples must be tested before and after the installation of a new air purification filter.

“It’s critically important to test regularly and follow the maintenance recommendations in the owner’s manual,” explained Ochoa. “This helps to ensure that your system is performing at optimal levels and safeguards your firefighters.”

In 2008, a new chapter on Compressed Breathing Air Systems (Chapter 7) was added, focusing on four areas – installation, compressors, maintenance and Records – to ensure proper functioning of the systems.

- Installation: Breathing air compressors must be installed, operated and maintained in accordance with the compressor manufacturer’s instructions.

- Compressors: Oil-lubricated compressors must be equipped with a tamperproof carbon monoxide (CO) monitor with both audible and visual alarms that shut down the compressor when the CO level exceeds 5.0 ppm and have a resolution of at least 1 ppm.

- Maintenance: The breathing air system compressor must be operated at least 30 minutes each week with two condensate drain cycles.

- Records: The testing lab must be accredited, and the lab’s current designation are included in the air quality test results.

“The addition of Chapter 7 helps to reinforce how essential it is for every aspect of the compressed air breathing system to function properly,” said Ochoa.

The most recent edition of NFPA 1989 was issued December 17, 2012. In addition to some editorial revisions, it includes new requirements for air storage cylinders, air sampling requirements, and cylinder recharge areas posting requirements.

Fortunately, implementing NFPA 1989 and testing your system is relatively simple. The first step is to find an accredited laboratory that specializes in testing and analysis of compressed breathing air.

“Trace does not sell compressors, filters, or provide maintenance services. There’s no conflict of interest, so you know you’ll receive an unbiased third-party analysis,” Ochoa explained.

The next phase is to get the hardware or testing kit and take the required samples. Trace Analytics’ AirCheck Kit provides step-by-step manuals and online videos to help you get an air sample that is representative of the air used to fill your SCBAs. The kit can be used to test your breathing air quality from your compressor or cascade system. If you prefer, Trace can send a distributor to your station to take samples.

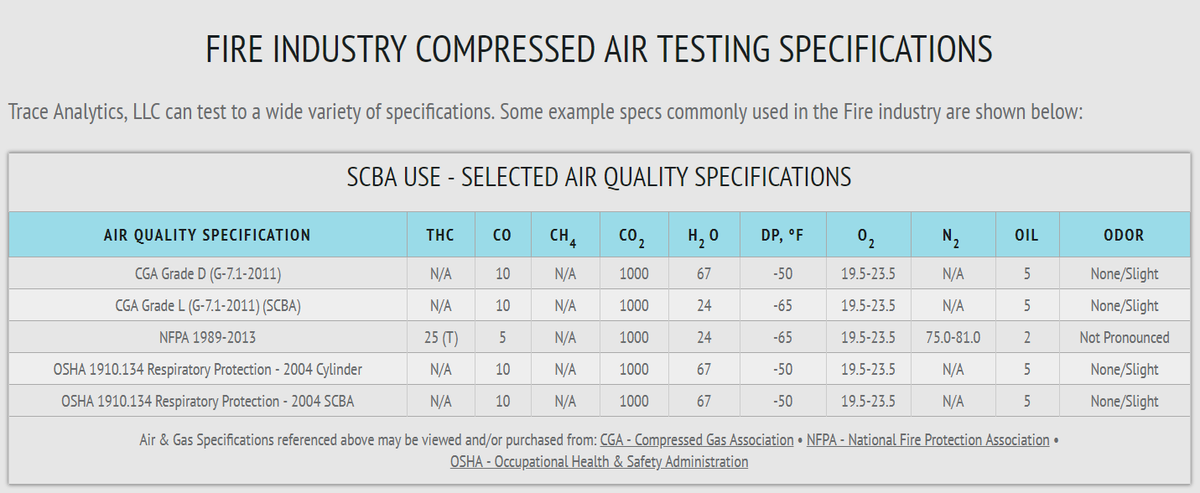

Once you obtain the samples, return it to the laboratory for testing. You’ll receive a full report on your desired specification that you can post on the wall next to your compressor. See the most commonly used specifications below:

“Everyone wants to be absolutely certain that all precautions have been taken, the standards are enforced and ultimately, the air firefighters are breathing at any incident is clean,” said Ochoa. “Trace Analytics can help provide that peace-of-mind.”

Whether it’s on a fireground, a hazmat incident or in confined space, having confidence in your SCBA to provide clean, compressed breathing air is critical. Testing your compressed air with an accredited laboratory, such as Trace Analytics, a leader in compressed air laboratory testing since 1989, will allow you to comply with NFPA 1989 effectively.